In the world of Total Quality Management (TQM), decision-making and prioritization are critical for continuous improvement. One powerful tool that helps organizations make structured decisions is the 2×2 Matrix. This simple yet effective framework provides clarity when teams face multiple options and need to choose the most impactful actions. In this blog, we’ll explore what a 2×2 matrix is, its role in TQM, how to use it, and practical examples—all in easy-to-understand language.

What is a 2×2 Matrix?

A 2×2 Matrix is a visual decision-making tool that organizes options into four quadrants based on two key criteria. These criteria can vary depending on the context, but common pairs include:

- Impact vs. Effort

- Urgency vs. Importance

- Value vs. Risk

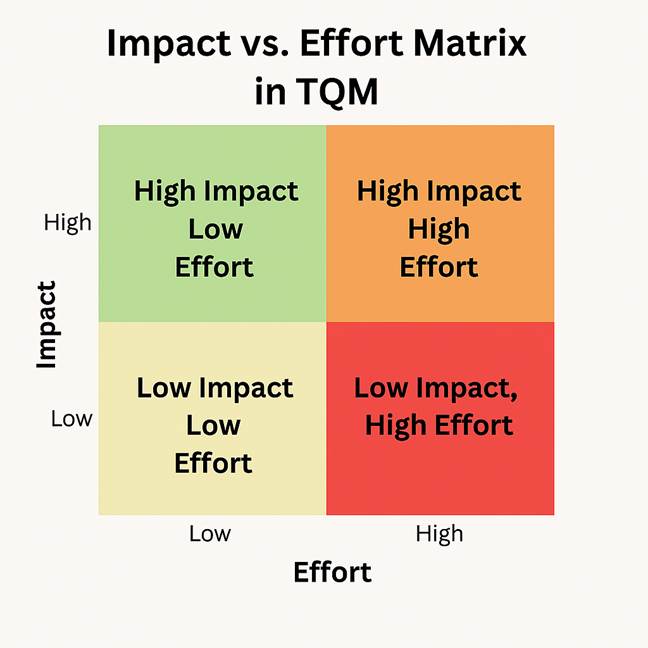

Each axis represents one criterion, and the intersection creates four quadrants. For example, in an Impact-Effort Matrix, the quadrants are:

- High Impact, Low Effort – Quick wins

- High Impact, High Effort – Strategic projects

- Low Impact, Low Effort – Low-priority tasks

- Low Impact, High Effort – Avoid or defer

This simple visualization helps teams focus on what matters most and avoid wasting resources on low-value activities.

Why is the 2×2 Matrix Important in TQM?

TQM emphasizes continuous improvement, customer satisfaction, and efficient resource utilization. The 2×2 matrix aligns perfectly with these principles because it:

- Prioritizes High-Value Actions: By plotting tasks based on impact and effort, teams can identify quick wins that deliver maximum benefit with minimal resources.

- Supports Lean Thinking: It helps eliminate waste by avoiding low-impact, high-effort activities.

- Facilitates Consensus: Visual representation makes it easier for teams to agree on priorities.

- Improves Decision Speed: Instead of debating endlessly, the matrix provides a structured approach for faster decisions.

The Four Color‑Coded Quadrants

🟩 Quick Wins (High Impact, Low Effort): Do now. Example: Add checklists at receiving to standardize inspection steps.

🟧 Strategic Projects (High Impact, High Effort): Plan as projects. Example: Implement automated data capture for in‑process measurements.

🟨 Nice‑to‑Haves (Low Impact, Low Effort): Keep in backlog. Example: Improve report formatting to make summaries easier to read.

🟥 Time Sinks (Low Impact, High Effort): Avoid or defer. Example: Rebuild a workflow without evidence of measurable quality benefit.

Visual Representation of Impact vs Effort Matrix:

Step‑by‑Step: How to Use the 2×2 Matrix in TQM

- Step 1: Choose your axes (Impact vs Effort or Urgency vs Importance).

- Step 2: List your options (training, poka‑yoke, inspection changes).

- Step 3: Agree on definitions (High/Medium/Low scales).

- Step 4: Plot items together in a workshop.

- Step 5: Decide and schedule actions based on quadrant.

- Step 6: Review and refine regularly.

How to Create a 2×2 Matrix in TQM

How to Create a 2×2 Matrix in TQM

Here’s a step-by-step guide:

Step 1: Define Your Criteria

Choose two factors that matter most for your decision. In TQM, common pairs include:

- Impact vs. Effort (for process improvements)

- Urgency vs. Importance (for corrective actions)

- Cost vs. Benefit (for quality initiatives)

Step 2: Draw the Grid

Create a square divided into four quadrants. Label the X-axis and Y-axis with your chosen criteria.

Step 3: List Your Options

Gather all potential projects, tasks, or solutions.

Step 4: Plot Each Option

Place each item in the quadrant that best represents its characteristics.

Step 5: Analyse and Decide

Focus on the top-left quadrant (high impact, low effort) for quick wins. Plan for high-impact, high-effort tasks as strategic goals.

Examples of 2×2 Matrix in Quality Management

- Impact-Effort Matrix for Process Improvement

- High Impact & Low Effort: Implementing visual inspection standards.

- High Impact & High Effort: Installing automated defect detection systems.

- Low Impact & Low Effort: Minor layout changes.

- Low Impact & High Effort: Redesigning entire plant workflow.

- Urgency-Importance Matrix for Corrective Actions

- Urgent & Important: Addressing a customer complaint immediately.

- Important but Not Urgent: Developing a long-term quality training program.

- Urgent but Less Important: Responding to non-critical audit findings.

- Neither Urgent nor Important: Cosmetic changes to reports.

- Cost-Benefit Matrix for Quality Investments

- High Benefit & Low Cost: Adding error-proofing devices.

- High Benefit & High Cost: Implementing advanced ERP systems.

- Low Benefit & Low Cost: Minor tool upgrades.

- Low Benefit & High Cost: Over-engineering packaging.

Benefits of Using 2×2 Matrix in TQM

- Clarity and Focus: Helps teams see priorities immediately.

- Resource Optimization: Ensures time and money are spent wisely.

- Collaboration: Encourages team discussions and alignment.

- Transparency: Provides a clear rationale for decisions.

Real Industry Example

1. Toyota’s Continuous Improvement (Kaizen)

Toyota uses the Impact vs. Effort Matrix to prioritize Kaizen activities. For example:

- High Impact, Low Effort: Adding visual indicators on assembly lines to reduce errors.

- High Impact, High Effort: Implementing automated quality checks across multiple plants.

- Low Impact, Low Effort: Minor adjustments in workstation layout.

- Low Impact, High Effort: Redesigning entire production flow without clear ROI.

This approach ensures that quick wins are implemented immediately while strategic projects are planned for long-term improvement.

2. Motorola’s Six Sigma Projects

Motorola, a pioneer in Six Sigma, uses a Cost vs. Benefit Matrix to select improvement projects:

- High Benefit, Low Cost: Training operators on defect detection.

- High Benefit, High Cost: Deploying advanced statistical process control systems.

- Low Benefit, Low Cost: Minor tweaks in documentation.

- Low Benefit, High Cost: Over-engineering packaging for non-critical parts.

This helps Motorola allocate resources effectively and maintain profitability while improving quality.

3. Nippon Steel’s Quality Initiatives

In steel processing plants, the Urgency vs. Importance Matrix is applied for complaint resolution:

- Urgent & Important: Addressing surface defects reported by key customers immediately.

- Important but Not Urgent: Developing a long-term plan for automated inspection.

- Urgent but Less Important: Responding to minor audit findings.

- Neither Urgent nor Important: Cosmetic changes in reporting templates.

This ensures customer satisfaction and compliance with ISO/IATF standards.

4. Healthcare Industry

Hospitals use the Impact vs. Effort Matrix for patient safety improvements:

- High Impact, Low Effort: Introducing hand hygiene reminders.

- High Impact, High Effort: Implementing electronic health record systems.

- Low Impact, Low Effort: Adding extra signage.

- Low Impact, High Effort: Redesigning entire hospital layout without clear benefits.

Limitations to Keep in Mind

While the 2×2 matrix is powerful, it has some limitations:

- Oversimplification: Complex decisions may need more than two criteria.

- Subjectivity: Placing items in quadrants often involves judgment.

- Risk of Ignoring Innovation: Focus on urgency and importance may overlook creative ideas.

Best Practices for Effective Use

- Define Clear Criteria: Be specific about what “impact” or “effort” means.

- Involve Stakeholders: Get input from all relevant team members.

- Review Regularly: Priorities can change; update the matrix as needed.

- Combine with Other Tools: Use alongside Pareto Analysis or Cause-and-Effect diagrams for deeper insights.

External Resources for Further Reading

- ProductPlan: 2×2 Prioritization Matrix Overview [productplan.com]

- Fibery Blog: How to Build a 2×2 Matrix [fibery.io]

- LogRocket: Using 2×2 Matrix for Decision Making [blog.logrocket.com]

- NumberAnalytics: Decision Matrix in TQM [numberanalytics.com]

Conclusion

The 2×2 matrix is the clearest way to choose the right quality actions. It turns long lists into a priority plan that your team understands and supports. Use Impact vs Effort to unlock quick wins and set strategic projects. When decisions demand more detail, add a weighted decision matrix. Together, these tools bring clarity, speed, and alignment—the core of successful TQM.