Introduction

In the steel manufacturing industry, maintaining dimensional accuracy is crucial for ensuring high-quality products. One of the common defects that impact steel processing is camber. Camber is a deviation from the straightness of steel, causing a curve along its length. This defect can lead to several issues in downstream manufacturing processes, affecting product quality and operational efficiency. In this article, we will explore what is camber, its impact on manufacturing, causes, and effective solutions to eliminate this defect.

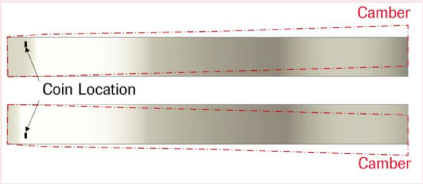

What is Camber?

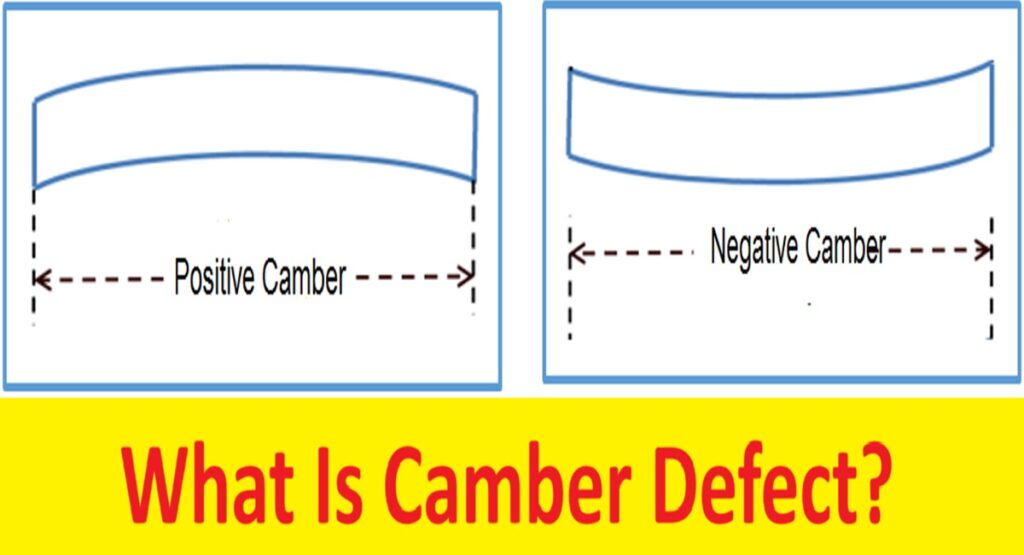

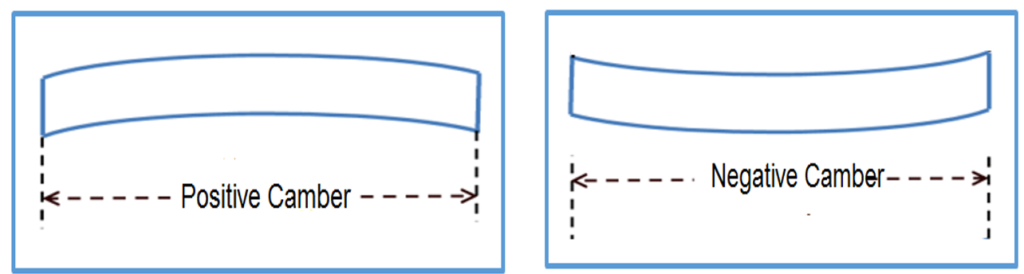

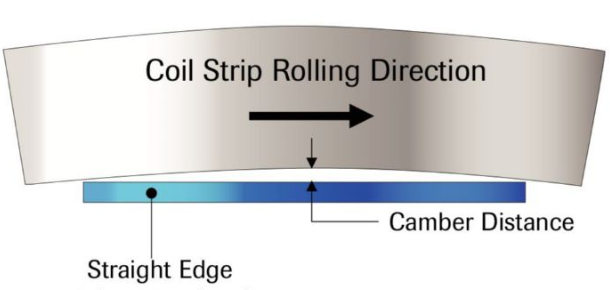

Camber in steel refers to an unintended curvature or deviation from a straight line along the length of a steel strip, sheet, or bar. It is a common defect found in rolled steel products, particularly in hot-rolled and cold-rolled coils. Camber occurs when one edge of the steel strip becomes longer than the other, leading to an uneven curvature.

How is Camber Measured?

Camber is measured as the maximum deviation from a straight line over a specific length. It is typically expressed in millimetres or inches over a defined length, such as 1 meter or 10 feet.

Impact of Camber Defect on Downstream Manufacturing

The presence of camber in steel products can significantly affect downstream manufacturing processes. Some of the key impacts include:

1. Processing Issues in Cutting & Slitting

- Camber affects the accuracy of cut-to-length operations.

- Causes misalignment during slitting and trimming.

- Leads to wastage due to uneven cutting edges.

2. Assembly and Welding Problems

- Creates difficulties in welding joints and structural alignment.

- Increases rework time and affects productivity.

- Results in dimensional inaccuracies in fabricated structures.

3. Complications in Roll Forming & Bending

- It leads to irregular bends in sheet metal processing.

- Results in asymmetrical profiles in roll-formed components.

- Affects material flow in forming operations.

4. Poor Aesthetic & Surface Quality

- Uneven camber results in visual defects in finished products.

- Reduces customer acceptance and increases rejection rates.

- Affects the coating and painting process due to inconsistent surfaces.

5. Effect of Camber in Cold Rolling

- Camber in steel coils results in dimension variations during cold rolling.

- Causes horizontal deflection in the product, affecting tolerances.

- Leads to uneven material flow, impacting the final product consistency.

Causes of Camber Defect in Steel Manufacturing

Understanding the root causes of this defect is essential to take corrective actions. Some common causes include:

1. Uneven Rolling Conditions

- Improper setup of roll gaps leads to variations in elongation.

- Unequal forces applied to edges cause edge elongation and camber formation.

2. Improper Material Feeding in Rolling Mills

- Misaligned strip entry into rolling mills leads to differential elongation.

- Variations in material thickness cause uneven deformation.

3. Residual Stresses in the Steel Strip

- Uneven cooling during hot rolling introduces internal stresses.

- Residual stresses release during subsequent processing, causing curvature.

4. Incorrect Tension Control in Cold Rolling

- Improper tension settings cause edge elongation and camber.

- Variations in tension between the centre and edges lead to non-uniform stretching.

5. Inconsistent Material Properties

- Variations in chemical composition and mechanical properties affect rolling behaviour.

- Non-uniform hardness distribution contributes to differential elongation.

6. Material variations:

- Inconsistent thickness or composition within the steel can also cause this defect.

How to Eliminate Camber Defect in Steel Manufacturing

Addressing this defects requires a systematic approach to process control, equipment maintenance, and quality monitoring. Below are some effective solutions:

1. Optimized Rolling Mill Setup

- Ensure uniform roll gap adjustment to maintain even elongation.

- Use advanced roll shape control (crown and roll bending) to minimize this issue.

- Implement automatic gauge control (AGC) for consistent thickness.

2. Proper Material Handling & Alignment

- Use precision guide rollers and edge guides for proper material feeding.

- Align strips properly before entering the rolling mill.

- Regularly check and calibrate entry and exit guides.

3. Stress Relieving and Controlled Cooling

- Implement controlled cooling processes to reduce residual stresses.

- Use heat treatment techniques such as annealing to relieve stresses.

- Ensure uniform cooling by optimizing air and water quenching.

4. Advanced Tension Control in Cold Rolling

- Use tension sensors and feedback control systems for uniform tension.

- Apply differential speed rolling to balance elongation.

- Optimize tension between the centre and edges.

5. Using High-Strength Leveller & De cambering Unit

- Integrate a high-strength leveller to remove this before further processing.

- Use a De cambering unit to streamline coil defects before entering the rolling and stamping line.

- Ensures better dimensional accuracy and improved product consistency.

6. Quality Monitoring & Process Automation

- Utilize laser-based measurement systems for real-time camber detection.

- Implement automated camber correction systems in rolling mills.

- Conduct regular material property analysis to detect variations.

Practical Applications and Real-World Examples

Several industries are affected by this defects, including automotive, construction, and heavy machinery manufacturing. Below are some real-world examples:

1. Automotive Industry

- In car body panel production, excessive camber can lead to misalignment in stamping dies.

- Affects the fit and finish of body panels.

2. Structural Steel Fabrication

- Camber in steel beams and channels causes alignment issues in welded structures.

- Leads to additional rework and increased labour costs.

3. Pipe and Tube Manufacturing

- Camber in strip steel leads to improper seam welding in pipe forming.

- Results in weak joints and defects in final products.

External References and Further Reading

For more insights on this defect and solutions, check out the following links:

- X-bar & R vs. I-MR Charts in SPC:

- What is Camber Defect in Steel Manufacturing?

- Top 15 MNCs Every Mechanical Engineer Dreams of Joining in 2025

- How to Digitize and Automate the CAPA Process

- Top 10 Essential Tools Every Mechanical Engineer Should Know

- What is GD&T (Geometric Dimensioning & Tolerancing) ?

- Principles of IATF 16949: A Guide to Quality Management

- The Evolution of IATF 16949: The Automotive Quality Standard

- Top Interview Questions Related to SPC ,Cp and Cpk